1. Multi Cyclone Booth Overview

A Multi Cyclone Powder Coating Booth is an advanced finishing system that uses centrifugal separation technology to achieve 95-98% powder recovery rates. Unlike standard filter booths, it features:

3-6 cyclone chambers for staged powder separation

No consumable filters (eliminates replacement costs)

Continuous recycling of overspray powder

Best for: High-volume production requiring maximum material reuse and minimal downtime.

| Feature | Multi Cyclone Booth | Standard Filter Booth |

|---|

| Recovery Rate | 95-98% | 70-85% |

| Maintenance | No filter changes | Weekly filter replacements |

| Downtime | <5 min color change | 15-30 min color change |

| Energy Use | 30% less fan power | Higher airflow needed |

| Long-term Cost | Lower operational cost | Higher consumable costs |

3. System Components

① Cyclone Array – 3-6 progressively finer cyclones

② Powder Silos – Separate chambers for each color

③ Airlock Valves – Prevent cross-contamination

④ Vortex Generator – Creates optimal airflow patterns

⑤ Control Panel – Adjusts suction power per cyclone

4. Pricing & ROI Analysis

| Booth Size | Price Range | Payback Period |

|---|

| Small (4'x4') | 25,000−50,000 | 12-18 months |

| Medium (6'x8') | 60,000−100,000 | 10-15 months |

| Large (10'x20') | 120,000−250,000 | 8-12 months |

ROI Factors:

5. Optimal Operation Guide

Step 1: Set airflow to 1,200-1,800 CFM (varies by booth size)

Step 2: Maintain 15-25 m/s inlet velocity for proper cyclone action

Step 3: Use dedicated cyclones per color when possible

Step 4: Monitor pressure differentials (indicates cyclone efficiency)

Step 5: Empty collection bins at 80% capacity

6. Maintenance Protocol

Daily:

Weekly:

Measure pressure drops

Clean interior surfaces

Lubricate moving parts

Annually:

7. Top Manufacturers Comparison

| Brand | Key Feature | Best For |

|---|

| Nordson | Smart cyclone control | Automotive |

| Gema | Compact designs | Small shops |

| Col-Met | Heavy-duty cyclones | Industrial |

| Wagner | Budget systems | Startups |

8. Troubleshooting Common Issues

Problem: Powder Carryover

➔ Solution: Increase secondary cyclone speed

Problem: Uneven Recovery

➔ Solution: Rebalance airflow between cyclones

Problem: Excessive Noise

➔ Solution: Check for internal abrasion

Problem: Color Contamination

➔ Solution: Purge system for 5 mins between colors

9. Future Innovations

AI airflow optimization – Auto-adjusts cyclones in real-time

Magnetic cyclones – For metallic powder separation

Self-cleaning designs – Ultrasonic vibration cleaning

This Multi Cyclone Powder Coating Booth guide provides powder coating professionals with data-driven insights for selecting, operating, and maintaining the most efficient recovery systems on the market. The technology delivers unmatched powder savings for operations coating 50+ parts/day.

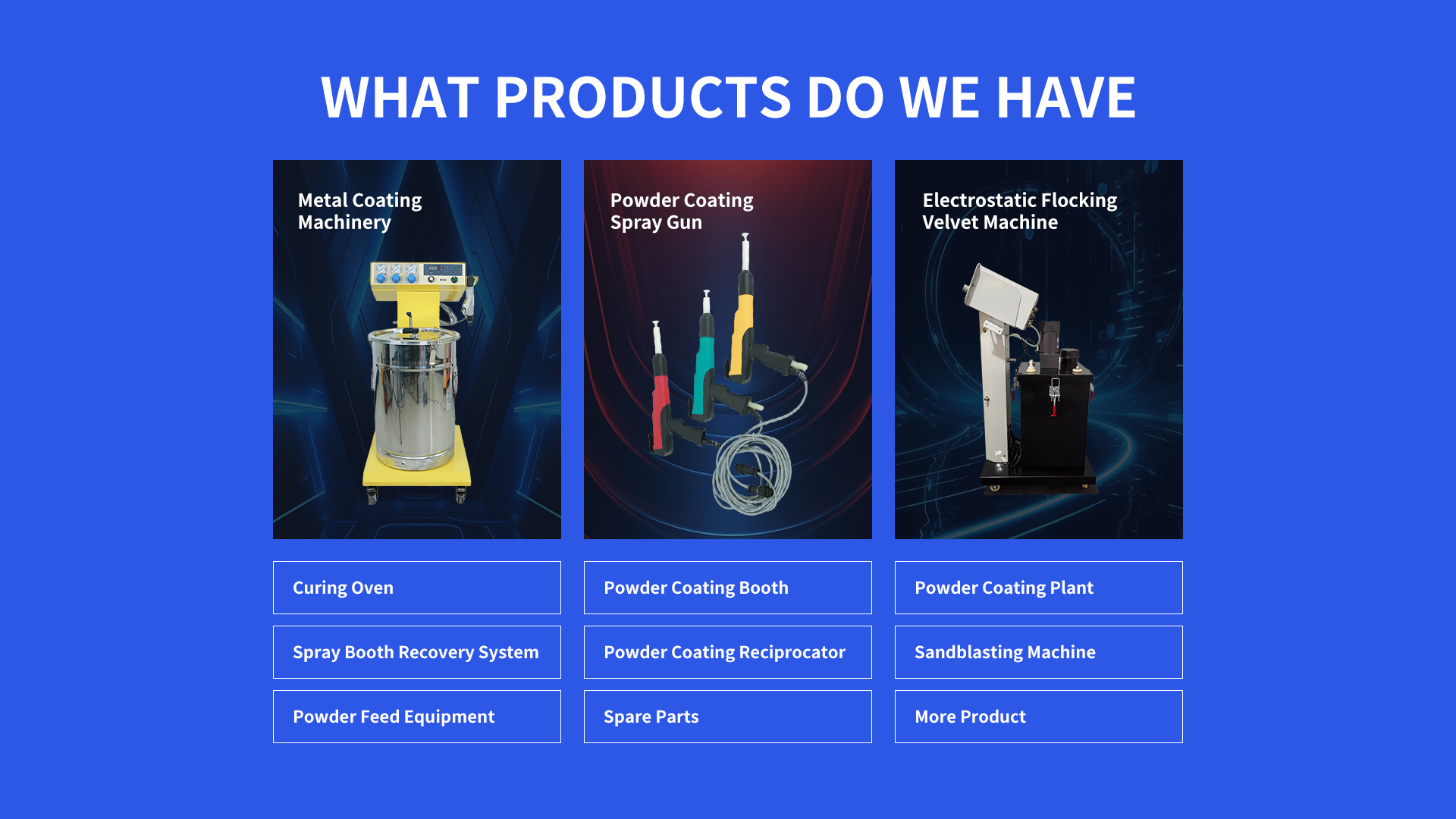

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com